|

|

GK Series - Horizontal Automatic Peeler Centrifuge

收藏

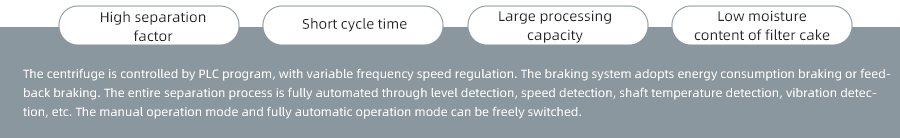

Product Introduction The GK type horizontal centrifuge is a fully automatic filtration centrifuge that operates continuously, intermittently, with a wide scraper and high-speed scraping. It can complete processes such as feeding, separation, washing, dehydration, unloading, and blowback at full speed. Commonly used for washing and solid-liquid phase separation of suspension media containing solid particles.

Scope of application

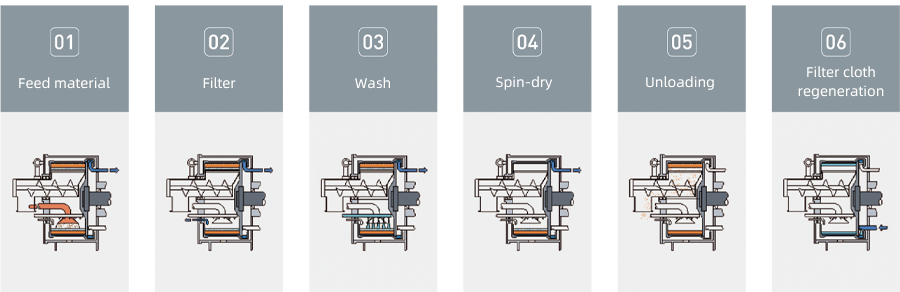

Workflow

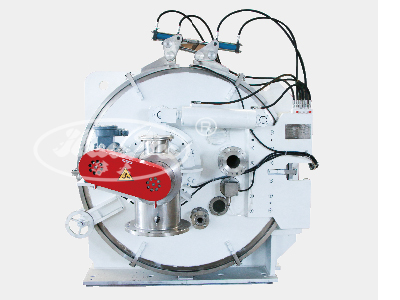

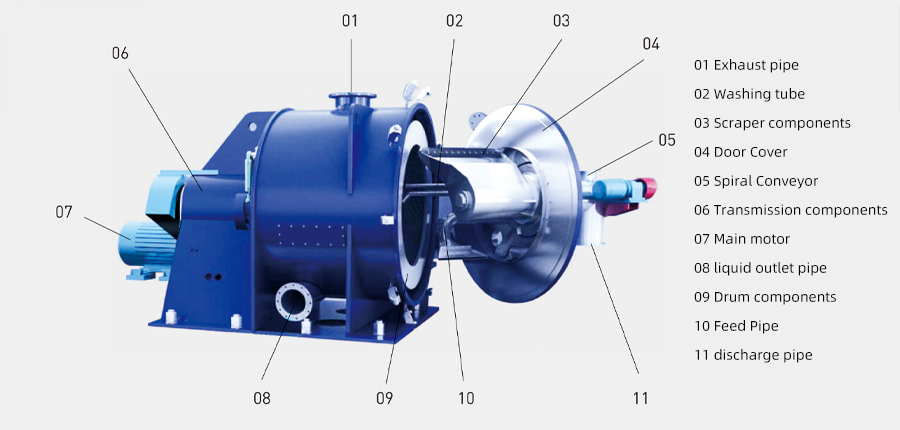

Dovetail slot design is adopted for door and base fitting flange to ensure reliable sealing. Full-hydraulic locking door and dual-locking protection are designed to ensure structural reliability and easy operation. Enclosed and explosion-proof design is employed for the whole structure to meet the GMP standards and the requirements for the application in flammable and explosive places of the pharmaceutical industry. Cake layer controller is configured to effectively control the thickness material layers, prevent overload operation, and avoid overflowing of materials.

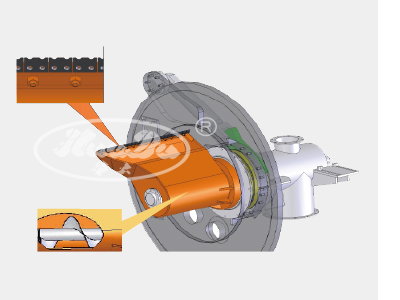

Hydraulic drive is adopted to ensure stable discharge. Detachable were-resistant hard-alloy blades are configured to expand the service life. Spiral discharge is adopted to ensure high collection rate of cakes and effectively prevent the blockage of materials. Equipment is supported by front and rear rolling bearing, with high rigidity and small revolving resistance. Peeler support is welded and polished as a whole, with high structural strength and high rigidity to ensure smooth scrapping.

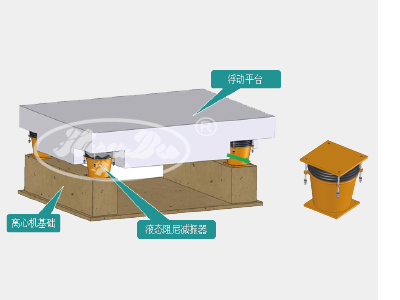

•Maximum service life of 30 years. •Large bearing capacity and good vibration attenuation effect. •Anti-slip base plate, without fixing the equipment with bolts. •Integrated design of floating platform and vibration attenuation system. •Dynamic load isolated positively, with no need to lay a foundation, easier to be installed. •Imported damper adopted for the vibration absorber, with special structural design to effectively improve the vibration isolating capacity as well as the equipment running safety and stability.

•Integrated design for the equipment base, which is manufactured as a whole to ensure both aesthetic appearance and production safety. •Coaxial machining for the front and rear bearings to ensure high coaxial precision. •Ion plating process employed for the spindle sleeve to resist wear and corrosion, and realize a longer service life. •Welded as a whole to eliminate stress, with high strength and strong vibration resistance. •Multiple sealing structures such as lip seal, air-tight seal and labyrinth seal adopted to ensure reliable sealing for transmission. •Forcible lubricant spraying mode adopted to ensure good lubricating and cooling effect. •Devices for detecting the temperature, velocity, vibration, etc. are configured for the spindle assembly to realize real-time monitoring of the equipment's operation. Structural diagram

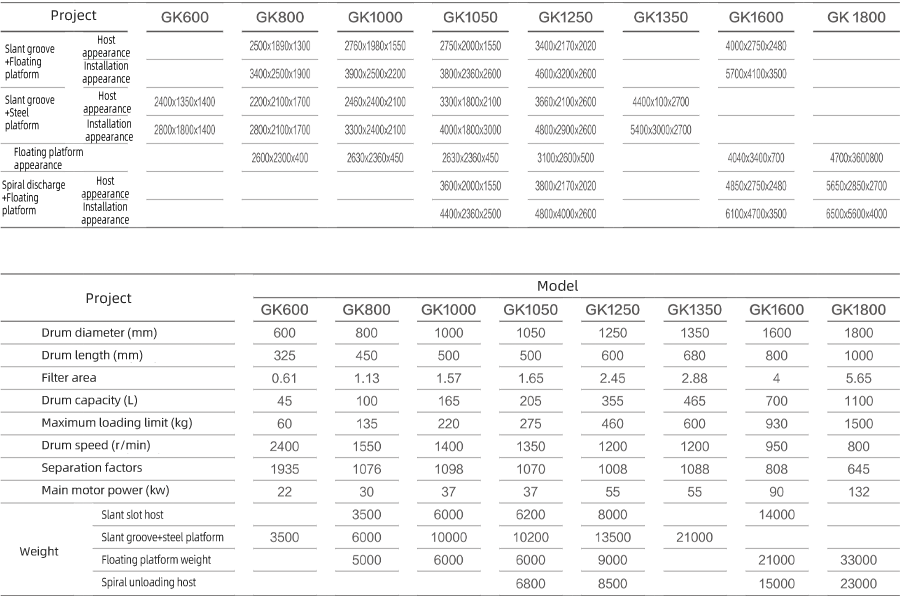

Technical Parameter

|

·focus

·professional

·innovation

Contact us

18 Qinxing Road, Zhangjiagang Economic and Technological Development Zone, Zhangjiagang

The general manager:15995988198

Mail:huada@huada.com.cn

Service:0086-512-58299937

Copyright jiangsu Huada Centrifuge Co., LTD. All Rights Reserved