|

|

Skid-mounted Sludge Dewatering Integrated System

收藏

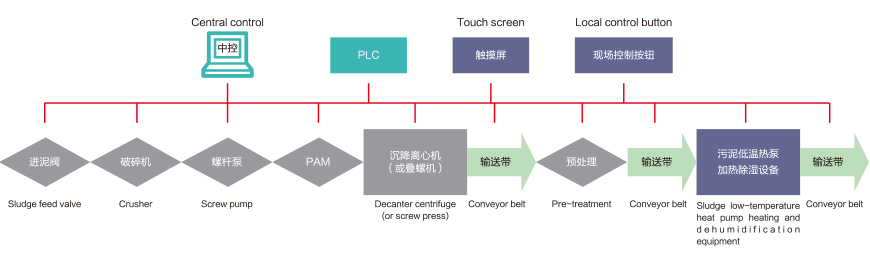

The centrifugal sludge dewatering and drying equipment produced by our company, usually used for sludge thickening and dewatering, is mainly composed of a LW series decanter centrifuge (or screw press), a full-automatic flocculant preparation and dosing device, a sludge crushing and cutting machine, a sludge feed pump, a dosing pump, a shaftless screw conveyor, a flowmeter, a control valve and a complete full-automatic control system. Characterized by advanced structure, reasonable configuration, high degree of automation, continuous airtight operation, safe and reliable operation, etc., it is applicable to the treatment of municipal sewage, rural sewage, hospital sewage, etc. as well as various types of industrial sewage.

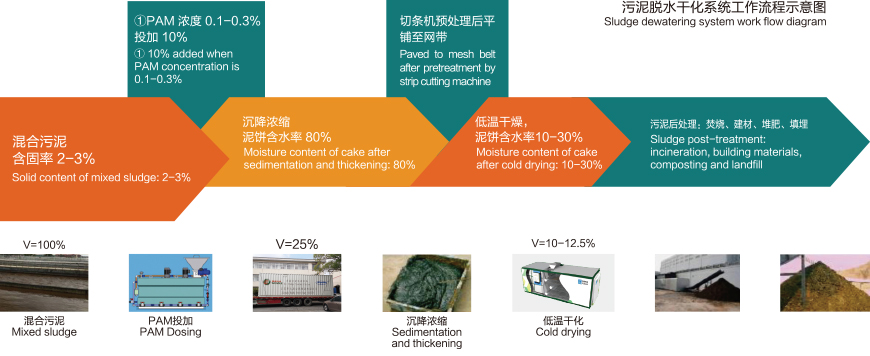

· Product Configuration The mixed sludge of urban sewage after primary and secondary sedimentation usually has a solid content of about 2-3%. After being dehydrated and concentrated by a horizontal screw sedimentation centrifuge (or belt filter, stack dewatering machine), the discharged sludge has a moisture content of about 80-85%. It then enters a low-temperature heat pump heating and dehumidification equipment for dehumidification and drying. The treated sludge has a moisture content of about 30%, creating conditions for harmless treatment of sludge, such as incineration or pyrolysis before being reused.

· DCS Control

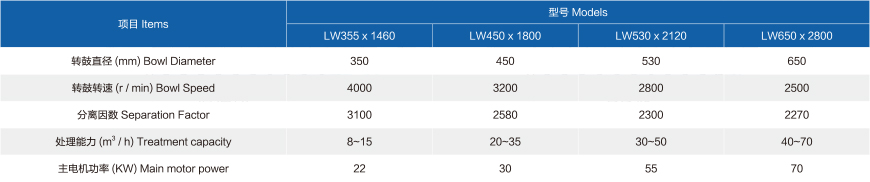

Bowl speed: The bowl is designed with high speed and large separation factor, which can effectively clarify tiny particles with size ≥5μm. Length-diameter ratio: The actual effective length-diameter ratio of the bowl is ≥4, and the sedimentation distance is long, which increases the clarification and dewatering time of the sludge in the bowl. BD baffle: There is a circular baffle between the scroll sedimentation section and drying section, which squeezes the sludge in the settling section into the drying section, so that the moisture content of the sludge is lower; meanwhile, it cuts off the connection between the sludge and the clarified liquid. The depth of the liquid pool can be greater than the slag outlet, and the deeper the liquid pool is and the longer the process takes, the better the clarification effect is.

|

·focus

·professional

·innovation

Contact us

18 Qinxing Road, Zhangjiagang Economic and Technological Development Zone, Zhangjiagang

The general manager:15995988198

Mail:huada@huada.com.cn

Service:0086-512-58299937

Copyright jiangsu Huada Centrifuge Co., LTD. All Rights Reserved