|

|

LWX Decanter Centrifuge

收藏

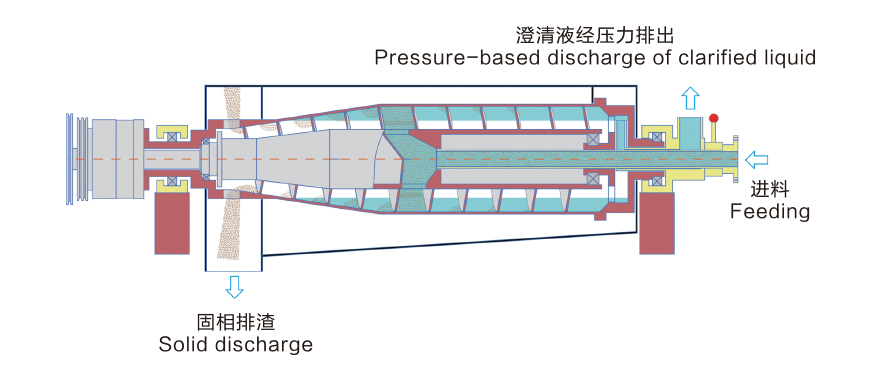

The material enters through the feed pipe, and under the action of centrifugal force, the solid phase material settles on the drum wall to form a sediment layer, while the liquid phase material forms a liquid phase ring. From the drum wall inward, the solid phase layer and liquid phase layer are formed in sequence. The spiral continuously pushes the solid material deposited on the drum wall to the cone end of the drum, and discharges it outside the machine through the slag discharge outlet. The liquid phase is discharged by the centrifugal pump at the large end of the drum.

The separated liquid is discharged by a centripetal pump with a certain pressure, which can horizontally transport the mother liquor to a certain distance, replacing a transfer pump and saving energy; In addition, the liquid is discharged by a centripetal pump and is not in the same chamber as the solid discharge, completely eliminating the possibility of small liquid droplets coming into contact with the solid phase again after the mother liquor is discharged. It has a high degree of cleanliness and is suitable for production fields such as medicine and food.

|

·focus

·professional

·innovation

Contact us

18 Qinxing Road, Zhangjiagang Economic and Technological Development Zone, Zhangjiagang

The general manager:15995988198

Mail:huada@huada.com.cn

Service:0086-512-58299937

Copyright jiangsu Huada Centrifuge Co., LTD. All Rights Reserved