|

|

PGZ Vertical Bottom Discharge Scraper Centrifuges

收藏

Product Introduction The PGZ series products retain the advantages of LGZ type products while adopting a fixed flip design, which is particularly suitable for separating toxic, volatile, flammable and explosive materials.

Scope of application Suitable for solid-liquid separation of fibrous suspensions with particle sizes ranging from 10um to several millimeters and solid contents of 5% to 40%, high viscosity, fine particle size, toxic, flammable and explosive materials. It has the characteristics of sterile hygiene, sealed explosion-proof, and multiple safety protections. It can operate in high-altitude conditions and has been widely used in industries such as pharmaceuticals, fine chemicals, new energy, and food.

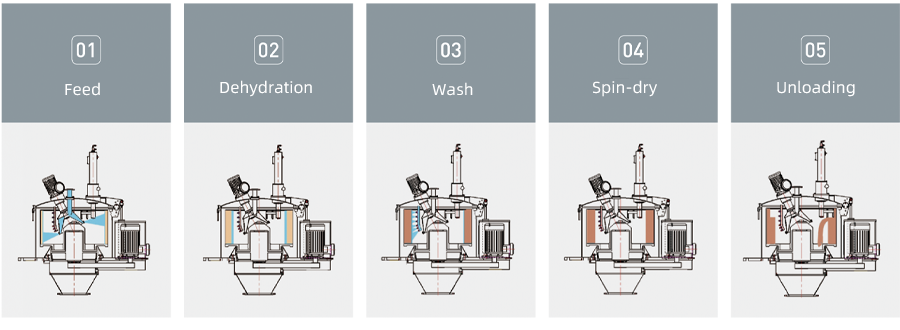

Workflow

working principle The motor drives the drum to rotate at high speed through a belt, and the material to be separated enters the high-speed rotating centrifuge drum through the feeding system under pre programmed control. Under the action of centrifugal force field, the material is filtered through the filter medium (filter cloth/screen), and the liquid phase is discharged outside the machine through the outlet pipe, while the solid phase is trapped in the drum. The material detection device detects the filling position of the material in real time, and stops feeding when the filter cake in the drum reaches the specified loading amount of the machine. Then wash and spin dry the filter cake. After the filter cake meets the requirements for dehydration, the centrifuge reduces the scraping speed, and the scraper device scrapes the filter cake under liquid (pneumatic) control and discharges it through the discharge port at the lower part of the centrifuge. Main features It is mainly used for solid-liquid separation of suspensions containing solid particles, and can also be used for solid-liquid separation of fibrous materials. Especially for the separation of high viscosity, fine particle size, toxic, flammable and explosive materials. Pharmaceutical products such as antibiotics, vitamins, pharmaceutical intermediates, salt, monosodium glutamate, food additives, starch, sugar, chemical seasonings, chemical raw materials such as ammonium sulfate, gypsum, saltpeter, copper sulfate, potassium oxide, borax, dyes, pigments, resins, pesticides, and solid-liquid separation work in industries such as mining and environmental protection. The centrifuge has a high degree of automation, a large processing capacity, and can be remotely controlled.

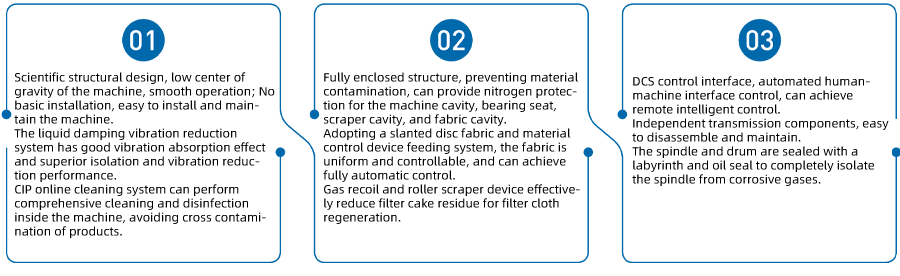

Main advantages and features

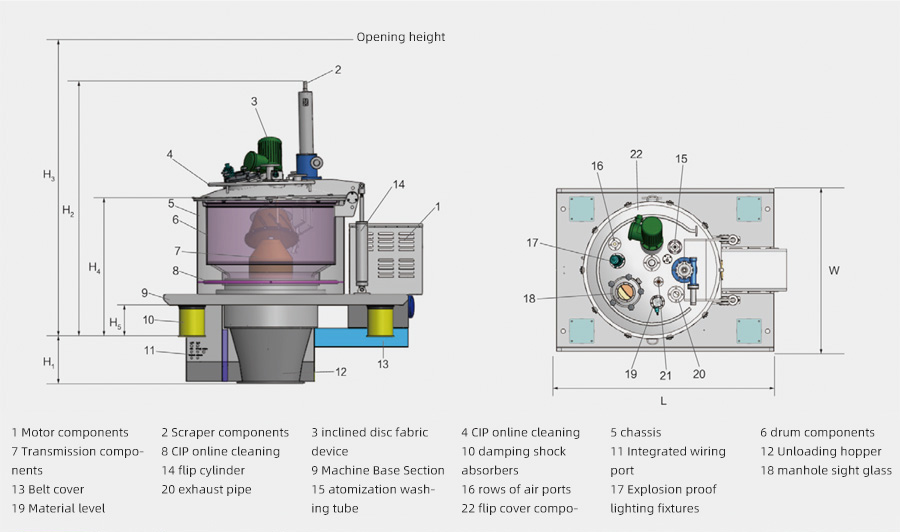

Structural diagram

Main technical parameters  |

·focus

·professional

·innovation

Contact us

18 Qinxing Road, Zhangjiagang Economic and Technological Development Zone, Zhangjiagang

The general manager:15995988198

Mail:huada@huada.com.cn

Service:0086-512-58299937

Copyright jiangsu Huada Centrifuge Co., LTD. All Rights Reserved