|

|

Vertical Bottom Discharge Scraper Centrifuges(Pharma Centrifuges)

收藏

Main purpose Mainly used for solid-liquid separation of suspensions of various solid particles, and can also be used for solid-liquid separation of fibrous materials. Especially for the separation of high viscosity, fine particle size, toxic, flammable and explosive materials, such as antibiotics, vitamins, pharmaceutical intermediates and other pharmaceutical products, food such as salt, monosodium glutamate, food additives, starch, sugar, chemical seasonings, chemical raw materials such as ammonium sulfate, gypsum, saltpeter, copper sulfate, potassium chloride, borax, dyes, pigments, resins, pesticide agents, lithium battery ternary precursor new energy industry, as well as solid-liquid separation in mining, metallurgy, environmental protection and other industries. PQLD Clean Type Adopting a full flip design, the structural components of the whole machine have smooth and flat transitions, effectively eliminating hygiene blind spots. It can be used for comprehensive cleaning of the centrifuge cavity, thoroughly removing residues and avoiding cross contamination of materials. Suitable for separating materials with high requirements for purity, hygiene, etc. working principle

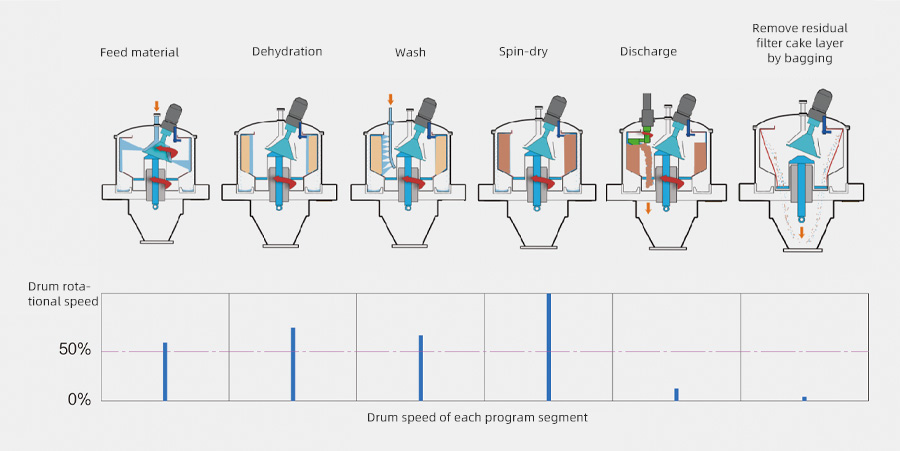

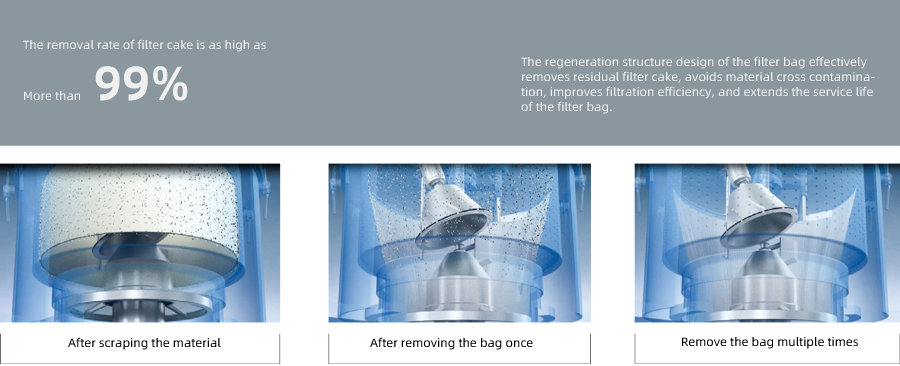

The material to be separated is fed into the high-speed rotating centrifuge drum through the feed pipe. Under the action of the centrifugal field, the material is filtered through the filter cloth, and the liquid phase is discharged through the outlet pipe, while the solid phase is trapped in the drum. When the drum is filled with materials, stop feeding and dehydrate: wash the filter cake while filtering out the washing solution. The centrifuge continues to rotate and spin dry the filter cake. After the filter cake meets the separation requirements, the centrifuge slows down and the filter cake is scraped off by a scraper and discharged from the bottom outside the machine. The centrifuge slows down again, and the pneumatic bag pulling device moves back and forth up and down to shake off the residual filter cake, achieving complete removal of the filter cake. Main features

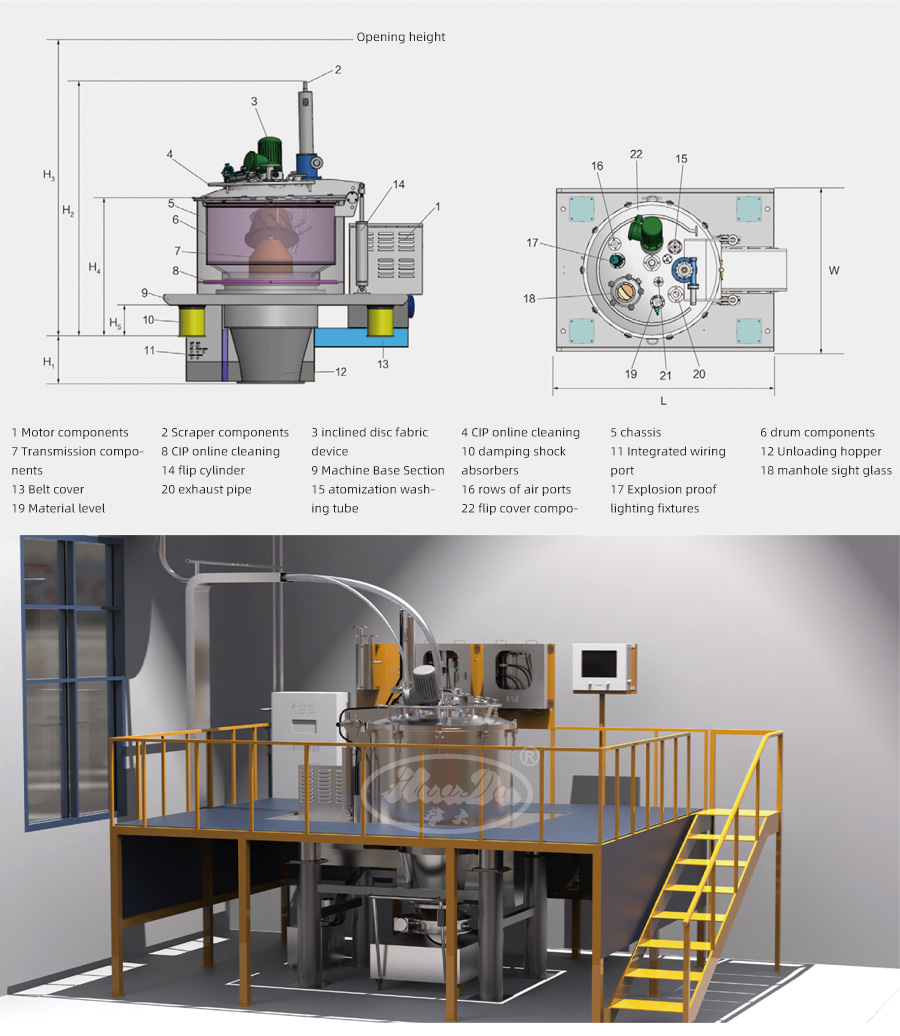

Structural diagram

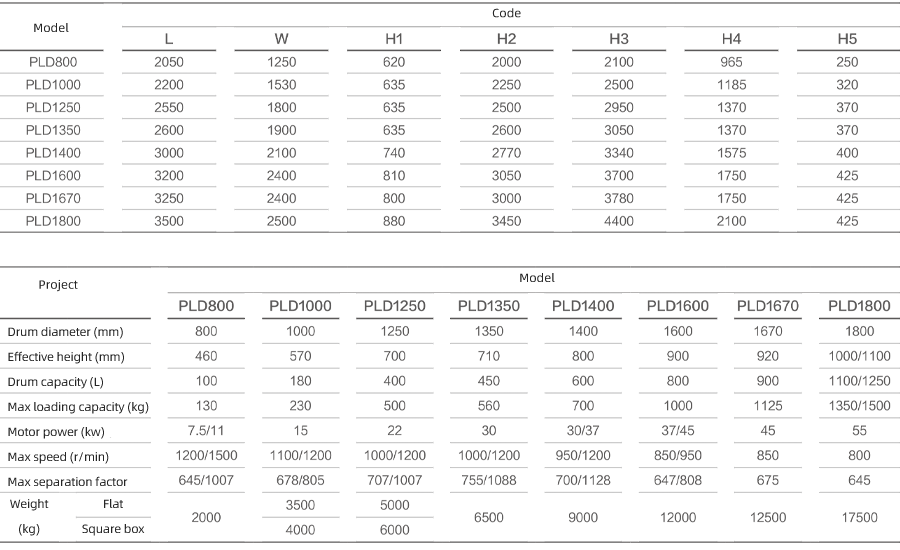

Main technical parameters

Product configuration selection

|

·focus

·professional

·innovation

Contact us

18 Qinxing Road, Zhangjiagang Economic and Technological Development Zone, Zhangjiagang

The general manager:15995988198

Mail:huada@huada.com.cn

Service:0086-512-58299937

Copyright jiangsu Huada Centrifuge Co., LTD. All Rights Reserved